|

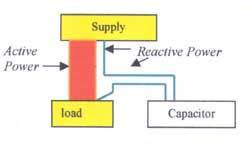

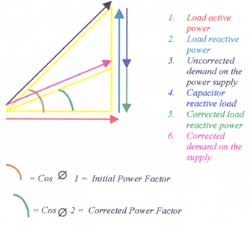

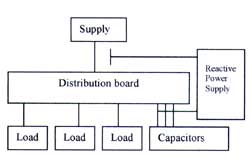

To automatically correct the power factor of a load, a number of capacitors are connected to the supply.

The capacitors are controlled by a microprocessor based relay which continuously monitors the reactive power

demand on the supply. The relay connects and/or disconnects the capacitors to compensate for the reactive power of the total load. This reduces the overall demand on the supply. Systems are manufactured utilising capacitors of either MKP, MKK or MPP/MKV technology. A typical power factor correction system would incorporate a number of capacitor sections (stages) determined by the characteristics and the reactive power requirements of the installation under consideration. |

Switching stages of 25kVAr are usually employed. Larger sections (e.g. 50kVAr and above) are achieved by cascading a number of smaller sections.

This has the beneficial effect of reducing the inrush current to the capacitors and minimises supply disturbances. Where harmonic distortion

is of concern, appropriate systems are supplied incorporating detuning reactors. |